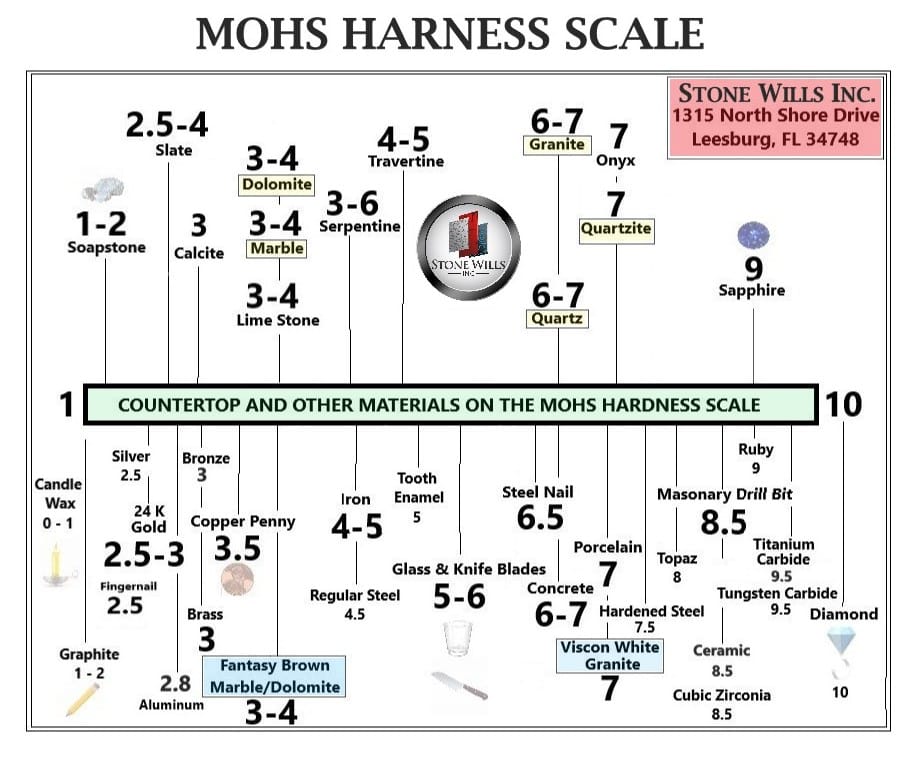

When selecting a stone countertop, homeowners often prioritize looks, color, and style—but one of the most critical and often overlooked aspects is hardness. The Mohs Hardness Scale, a system developed in 1812 by German mineralogist Friedrich Mohs, helps us understand the scratch resistance of minerals. Rated from 1 (talc) to 10 (diamond), this scale helps predict how durable a stone will be in real-world conditions like kitchen use, fabrication, and installation.

Let’s dive into how this scale applies to popular countertop materials like marble, quartzite, granite, dolomite, onyx, and quartz, and why it matters when it comes to performance and longevity.

Mohs Hardness Ratings of Popular Countertop Stones

| Stone Type | Approx. Mohs Rating | Characteristics |

|---|---|---|

| Marble | 3–5 | Softer, more porous; can scratch or etch easily |

| Dolomite | 3.5–5 | Slightly harder than marble, but still susceptible to scratching |

| Onyx | 3–4 | Very soft, used more decoratively than functionally |

| Quartzite | 7 | Extremely hard and durable, often confused with marble |

| Granite | 6–7 | Very durable, heat and scratch-resistant |

| Quartz (Engineered) | 7 | Man-made with high durability and consistent appearance |

How Metals Interact With Stone Surfaces

The Mohs scale isn’t just useful for comparing stones—it also helps determine what materials can scratch or damage your countertop. Everyday objects like kitchen tools, jewelry, or cleaning supplies can leave marks if they’re harder than the stone surface.

Here’s how common metals compare:

- Copper (e.g., coins) – Mohs 3: Can scratch marble, dolomite, and onyx.

- Steel (e.g., knives) – Mohs 4–5: Can scratch soft stones like marble or onyx; less likely to damage granite or quartzite.

- Stainless Steel (e.g., cookware) – Mohs 5.5–6.3: Can leave marks on dolomite or softer stones.

- Iron – Mohs 4–5: Same range as steel—can be problematic for soft stones.

- Tungsten Carbide (e.g., tools) – Mohs 8.5–9: Harder than nearly all countertop materials except diamond; can easily scratch everything but quartzite and quartz.

Bottom Line: If your countertop is marble, dolomite, or onyx, you’ll want to be extra cautious about metal utensils, jewelry, and cleaning products. Harder stones like granite, quartzite, and quartz are better suited for high-use areas.

Stone Fabrication and Installation Considerations

Each type of stone not only behaves differently in a home but also requires different methods of fabrication and installation.

Marble, Onyx, and Dolomite

- These stones are more delicate and can chip or crack during cutting and edge polishing.

- Water-jet or CNC cutting is often used for precision.

- They require careful handling and more support reinforcement during installation.

- Installers must use non-acidic sealants and adhesives to avoid chemical reactions.

Granite and Quartzite

- Due to their hardness, these stones require diamond blade tools and powerful saws.

- While harder to work with, they are less prone to breakage during transport and install.

- Their strength allows for longer overhangs and fewer seams in large countertops.

Quartz (Engineered Stone)

- Made from crushed quartz and resin, this material cuts more predictably than natural stone.

- No sealing is required, making installation faster.

- However, the resin component can be sensitive to heat, so proper insulation around cooktops is essential.

Choosing the Right Stone for Your Lifestyle

When making your choice, consider more than just beauty. Ask yourself:

- Will this be a high-traffic kitchen or a guest bathroom?

- Do you often cook with heavy pots and pans?

- Are you willing to seal and maintain your countertop annually?

If you want low-maintenance and high durability, quartz or quartzite are excellent choices. If you’re drawn to classic elegance and don’t mind some upkeep, marble or dolomite could be ideal. Onyx is best for statement pieces in low-use areas like backsplashes or bar tops.

Expert Help in Central Florida

At Stone Wills Inc., we specialize in custom fabrication and installation of all these stone types across Central Florida and surrounding areas. Our team understands the unique needs of each material—from the precision tools required for quartzite to the careful handling of marble demands. We help guide our clients not just in style, but in choosing the right material that will last for years to come.